OUR PLANTS

EXTRUSION

Our customers demands are speedily met throug the use of fully automatic extrusion presses of 1.250 and 1.100 tons, as well as a 2.200 ton fully automatic extrusion press capable of contributing to production where necessary. Our annual production capacity is 15.000 tons. The extrusion profiles in the required sizes are provided in the required mechanics and strength.

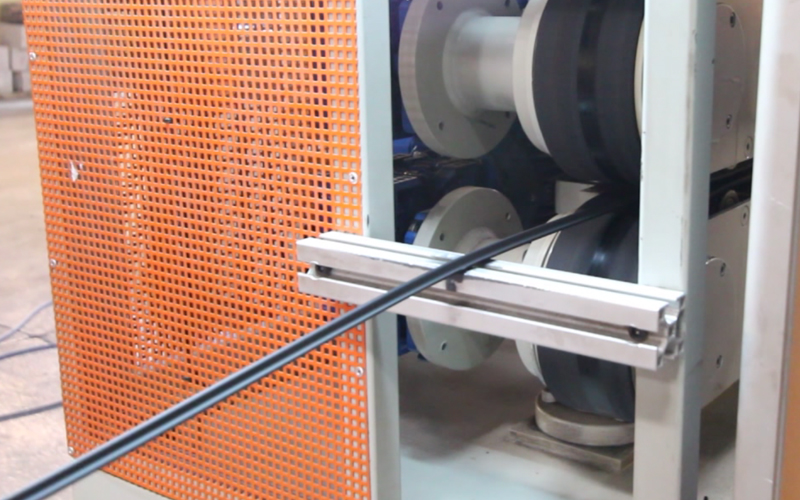

TPV-TPE GASKET

Thermoplastic Vulcanizate (TPV-TPE) is a positive product with colouring and welding capabilities that has a wide area of application in construction, PVC profiles, aluminium applications, the automotive industry and the domestic appliances industry. A variety of solutions can be developed according to technical design and intended purpose, and the design varies in line with intended use. Our TPV-TPE gasket plant serves our customers with an annual production capacity of 36.000.000 meters through the use of 3 extruders.

ELECTROSTATIC POWDERED PAINT

At our plant, which has a tunnel kiln, paint works are carried out at the required colours in compliance with international standards. Retrospection is made possible by operating all quality control processes and through the tests that are applied, and operations are carried out as an integrated plant thanks to our fully equipped laboratory that assures traceability. Paint belonging to all companies holding a qualicoat certificate may be used. All kinds of paint works, such as gloss, matt, semi-matt, hammered and lacquer paint are carried out.

MOULDING ROOM

Thanks to our state-of-the-art CNC Milling machine, extrusion mould production is carried out using manual lathe and wire erosion machines, and all processes of profile production is kept under control from beginning to end. Our moulding room has all the up-to-date technological infrastructure for computer-aided mould design and production.

POLISHING AND BURNISHING MECHANICAL PROCESSING

This is the department where all related processes including "perforation, mechanical processing, cutting in various sizes" are carried out to ensure surface alternatives and end-user satisfaction.

ELOXAL (ANODIC OXIDATION)

The colour surface use and oxidation resistance of the produced profiles are carried out at the required micron thickness and colour coating thanks to the surface processing plant automatic control system.